Choosing the right motor oil is crucial for your vehicle's health and performance. This listicle clarifies the key differences between synthetic and conventional oil, empowering you to make an informed decision. Discover how each type performs in 7 key areas, impacting your engine's longevity, efficiency, and your wallet. Understanding the synthetic vs conventional oil debate will help you select the best oil for your car, truck, or fleet vehicle, regardless of mileage or age. From chemical composition to cost, we'll cover it all.

Understanding the difference between synthetic vs conventional oil starts with knowing how they are made. This fundamental difference in their chemical composition and manufacturing process significantly impacts their performance, longevity, and suitability for different vehicles and driving conditions. Conventional oil is derived from crude oil extracted from the ground. This crude oil undergoes a refining process to remove impurities and separate the different components based on their boiling points. However, this process doesn't eliminate all impurities, and the resulting conventional oil contains a mix of hydrocarbon molecules with varying lengths and structures. This inherent variability can affect the oil's performance and consistency over time.

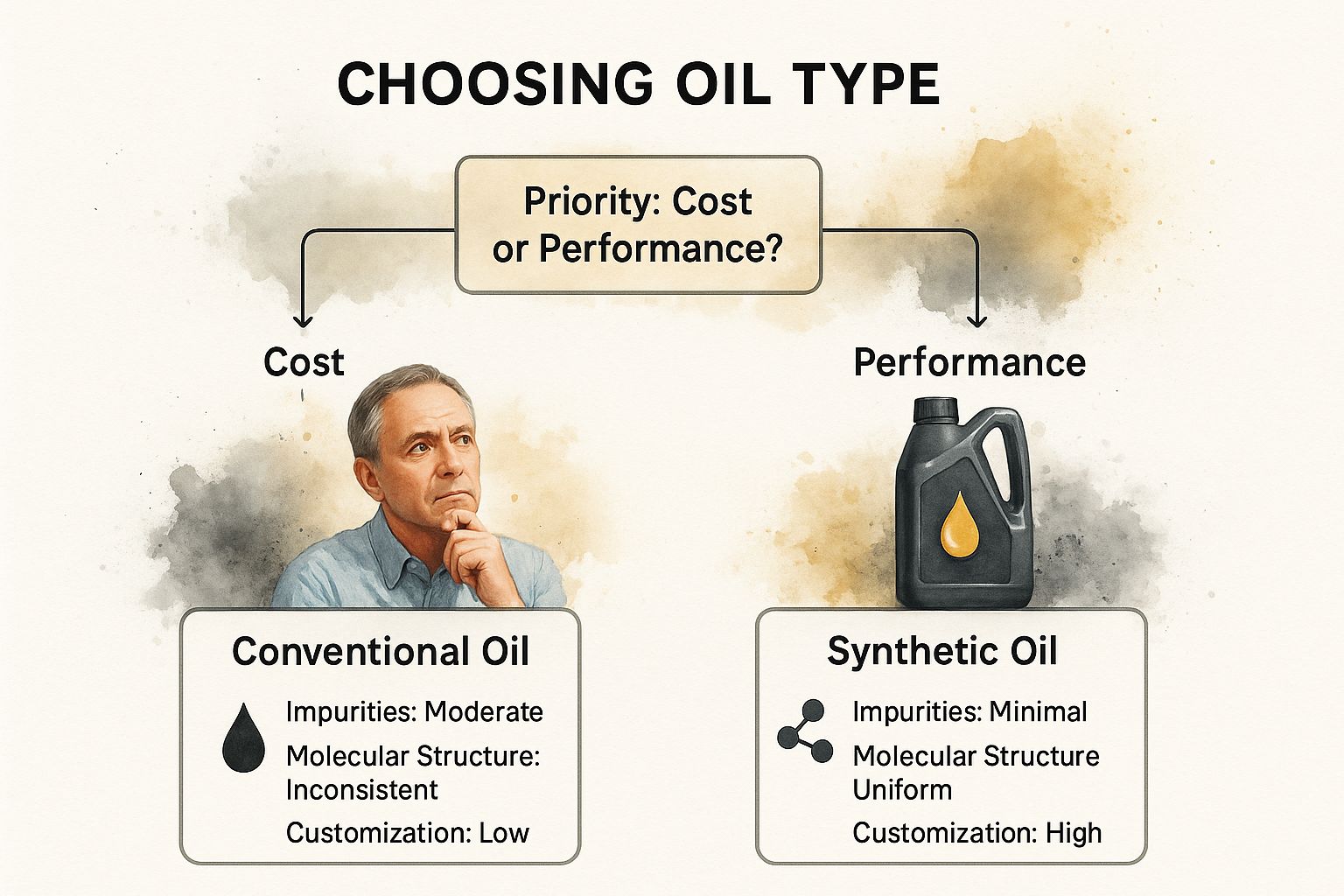

The infographic below provides a decision tree to help you choose between synthetic and conventional oil based on your specific needs and priorities. It visually represents the key decision points and outcomes related to oil selection.

Synthetic oil, on the other hand, is engineered from the ground up. While it can start with crude oil, it undergoes a more extensive refining process that breaks down the oil into its basic molecular components. These components are then reassembled or synthesized to create a uniform molecular structure. This process removes virtually all impurities and allows for precise control over the oil's properties, resulting in a higher quality lubricant. For instance, Pennzoil's PurePlus Technology converts natural gas into a pure synthetic base oil with significantly fewer impurities than conventional oil. This controlled manufacturing process allows manufacturers to tailor synthetic oils to meet specific performance demands, such as high-temperature stability, low-temperature fluidity, and resistance to oxidation.

The infographic highlights the key differences in the manufacturing process and resulting oil properties, guiding users through a simplified decision-making process. It considers factors like driving conditions, vehicle age, and desired performance level.

Conventional motor oils often rely on a significant amount of additives (15-25%) to compensate for the inherent limitations of the base oil. These additives address issues like viscosity index, detergency, and oxidation stability. Synthetic oils, due to their superior base oil quality, require fewer additives, leading to longer-lasting performance and reduced sludge formation.

This distinction between synthetic and conventional oil is crucial for vehicle owners in Richardson, especially those with demanding driving conditions. Families, commuters, first responders, and small business fleet managers all benefit from understanding how oil composition impacts their vehicles' performance, reliability, and longevity. Whether you're driving an older vehicle needing extra care, a high-mileage car used for commuting, or a fleet of vehicles demanding consistent performance, knowing the difference in oil types can inform your maintenance decisions. Synthetic oil's enhanced performance characteristics can be particularly beneficial for Richardson's climate, offering improved protection during hot summers and cold winters. This knowledge empowers drivers to make informed decisions that protect their investment and ensure optimal vehicle performance. While synthetic oil is typically more expensive, its superior performance and longevity can often translate into long-term cost savings through reduced maintenance needs and improved fuel efficiency.

One of the most critical differences between synthetic and conventional oil lies in their viscosity stability and performance across varying temperatures. Viscosity, simply put, is a measure of an oil's resistance to flow. Think of it like this: honey has high viscosity, while water has low viscosity. For proper engine lubrication, maintaining the correct viscosity is paramount. This is where synthetic oils truly shine in the synthetic vs conventional oil debate. Synthetic oils are engineered to maintain a more consistent viscosity across a much wider range of temperatures, unlike conventional oils which tend to thicken in cold weather and thin out excessively in high heat. These viscosity changes can significantly impact your engine's performance, the level of protection it receives, and even your fuel efficiency.

Synthetic oils can effectively maintain their viscosity in extreme temperatures, often ranging from -40°F to well over 400°F. This wide operating range ensures consistent lubrication and protection, whether you're starting your car on a frigid winter morning in Richardson or navigating heavy traffic on a scorching summer day. Conventional oils, on the other hand, have a much narrower effective temperature range. This means that in extreme cold, conventional oil can become thick and sluggish, making it difficult for the engine to turn over and increasing wear during those crucial first few minutes of operation. Conversely, in extreme heat, conventional oil can thin out excessively, losing its ability to effectively lubricate and protect critical engine components.

The viscosity index (VI) is a numerical value that indicates an oil's resistance to viscosity change with temperature. A higher VI indicates better stability. Synthetic oils typically boast VI ratings between 120 and 180, while conventional oils generally fall within the 80 to 120 range. This difference in VI highlights the superior temperature performance of synthetic oils.

Consider these real-world examples: Arctic expeditions rely almost exclusively on synthetic oils to ensure their vehicles operate reliably in extreme sub-zero temperatures. On the other end of the spectrum, high-performance engines in NASCAR race cars utilize synthetic oils to maintain critical lubrication and protection at operating temperatures exceeding 250°F. Even aircraft engines, which experience drastic temperature fluctuations at high altitudes, depend on the stability of synthetic oils for reliable performance.

Here are some actionable tips to consider: If you live in a region like Richardson, Texas, which experiences temperature extremes below 0°F in winter and above 100°F in summer, switching to synthetic oil can offer significantly improved engine protection and performance. Turbocharged engines, which generate considerably higher oil temperatures (often exceeding 300°F), also benefit greatly from the enhanced thermal stability of synthetic oils. If you continue to use conventional oil in extreme temperature conditions, be prepared for more frequent oil changes as the oil degrades faster. For those seeking maximum engine longevity and performance, particularly under demanding conditions, the investment in synthetic oil is often well worth the added cost. Whether you're a daily commuter, a family focused on safety, a member of the military, or a small business fleet manager, the viscosity stability offered by synthetic oil translates directly into improved reliability and reduced long-term maintenance costs.

When comparing synthetic vs conventional oil, the critical factor of engine protection and wear reduction takes center stage. The primary function of motor oil is to protect your engine's intricate components from the relentless forces of friction and wear. Both synthetic and conventional oils strive to achieve this, but their effectiveness differs significantly due to their inherent chemical composition and additive packages. These differences impact their ability to maintain protective films between moving parts, prevent harmful deposits, and neutralize corrosive acidic byproducts of combustion.

Synthetic oils are engineered with a uniform molecular structure, resulting in superior film strength between metal surfaces. This consistent, strong oil film is crucial, especially at high-stress contact points within the engine, such as between piston rings and cylinder walls. Furthermore, the advanced anti-wear additives blended into synthetic oils are more effective and stable in the synthetic base oil, providing enhanced protection against wear and tear. Conventional oils, derived from crude oil, offer basic protection but have limitations in extreme temperatures and high-stress environments. They are more prone to oxidation and thermal breakdown, leading to a decrease in their protective properties over time. This can result in increased engine wear, reduced efficiency, and potentially costly repairs.

This difference in engine protection directly translates to the longevity and performance of your vehicle. For instance, taxi fleets that have switched to synthetic oils report a significant 30-50% increase in engine life, demonstrating the long-term benefits of enhanced lubrication. Industry-standard Sequence VG engine tests also reveal that synthetic oils produce up to 40% less engine deposits, which can hinder performance and contribute to premature wear. Specifically, tests of Castrol EDGE with Titanium FST show up to 45% better wear protection compared to conventional oils in controlled laboratory conditions.

Tips for Choosing the Right Oil:

This superior engine protection offered by synthetic oils is recognized and endorsed by leading automotive manufacturers. GM requires synthetic oil in its high-performance Corvette engines, while Mercedes-Benz mandates it for warranty coverage, underscoring its importance for engine health and longevity. BMW, a pioneer in extended oil change intervals, relies on the durability of synthetic oils to allow for less frequent servicing.

The enhanced engine protection and wear reduction offered by synthetic oils make them a worthwhile investment for both new and older vehicles. While conventional oils offer a more budget-friendly option, the long-term benefits of synthetic oils, including reduced engine wear, improved fuel efficiency, and extended engine life, often outweigh the higher initial cost, especially for drivers in demanding environments like Richardson, Texas, and for those seeking to maximize the life and performance of their vehicles.

One of the most significant differences between synthetic and conventional oil lies in their longevity and required change intervals. This factor directly impacts your maintenance schedule, budget, and even the environmental impact of your vehicle. Understanding how oil change intervals are determined and the advantages of synthetic oil in this area is crucial for making informed decisions about your car's care.

Oil change intervals are based on an oil's resistance to oxidation, thermal breakdown, and contamination. Conventional oils, derived from crude oil, tend to oxidize and break down faster than synthetic oils. This degradation leads to the formation of sludge and acids, which can harm your engine. Synthetic oils, on the other hand, are engineered with uniform molecules and enhanced additives that provide superior resistance to these detrimental processes. As a result, synthetic oils maintain their protective properties for significantly longer periods.

The practical implication of this difference is that synthetic oils typically last 2-3 times longer than conventional oils before requiring replacement. While conventional oil might require changes every 3,000-5,000 miles, synthetic oils can often last between 7,500 and 15,000 miles, sometimes even longer. For example, many Toyota Prius models come with factory-fill synthetic oil and a recommended 10,000-mile change interval. Several European manufacturers also specify synthetic oils with 15,000-mile intervals, while specialized products like Mobil 1 Annual Protection are rated for up to 20,000 miles between changes. It's crucial to separate fact from fiction when it comes to oil changes. Many drivers operate under mistaken beliefs that can negatively impact their engine's health and performance. For instance, adhering to the '3,000-mile rule' is often unnecessary with modern oils and vehicles. If you're curious about other potential oil change misconceptions, take a look at this helpful resource: common oil change misconceptions.

This extended lifespan of synthetic vs conventional oil translates into several benefits:

Tips for Managing Oil Change Intervals:

By understanding the differences in longevity and change intervals between synthetic and conventional oil, and by following these practical tips, you can make the best choice for your vehicle's needs and your budget.

When weighing synthetic vs. conventional oil, fuel economy and efficiency are crucial factors, especially for Richardson commuters, families, and fleet managers seeking to minimize operating costs. Motor oil plays a surprisingly significant role in how efficiently your engine burns fuel. It all comes down to friction. The less internal friction within your engine, the smoother the components move and the less energy is wasted as heat. This translates directly into better fuel economy and improved overall engine efficiency.

Synthetic oils, due to their engineered molecular structure and superior properties, offer significant advantages in this area. They provide a lower friction coefficient compared to conventional oils, meaning less resistance between moving parts. This lower friction allows for the use of lower viscosity grades (e.g., 0W-20, 5W-30) without sacrificing engine protection. Lower viscosity oils flow more easily, further reducing internal resistance and maximizing fuel efficiency. Conventional oils, on the other hand, tend to create more internal resistance, especially during cold starts when the oil is thicker. This is particularly relevant for Richardson drivers experiencing cold Texas winters.

The difference in energy efficiency between synthetic and conventional oils becomes even more pronounced in extreme temperatures. Synthetic oils maintain their performance characteristics across a wider temperature range, ensuring optimal lubrication and minimizing friction in both scorching summers and freezing winters.

Examples of Successful Implementation:

Actionable Tips for Richardson Drivers:

When and Why to Use Synthetic Oil for Fuel Economy:

If you are a Richardson commuter seeking to improve fuel economy, a family looking to reduce vehicle operating costs, or a fleet manager aiming to maximize efficiency, synthetic oil is a worthwhile investment. It’s particularly beneficial for vehicles operating under demanding conditions, such as frequent stop-and-go driving, extreme temperatures, or heavy loads. For vehicles with start-stop technology, synthetic oil is often essential for proper system function.

Pioneering Companies:

Companies like Chevron (pioneered energy-efficient oil formulations), Honda (engine designs optimized for lower-friction oils), and Toyota (specifies synthetic oils to support hybrid efficiency) have been instrumental in demonstrating the fuel efficiency benefits of synthetic oils.

This focus on fuel efficiency makes the synthetic vs. conventional oil discussion a crucial one for any car owner, and particularly relevant to our target audience in Richardson. By understanding these differences, drivers can make informed decisions about maintaining their vehicles and maximizing their fuel budgets.

When comparing synthetic vs conventional oil, environmental impact and sustainability are increasingly important considerations. The ecological footprint of each oil type spans from its production all the way to its disposal. Understanding these implications helps make informed choices that benefit both your vehicle and the planet.

The production processes for synthetic and conventional oils differ significantly, leading to varying environmental impacts. Conventional oil relies heavily on crude oil extraction, a resource-intensive process with inherent environmental risks. While synthetic oil utilizes crude oil as a starting point, it undergoes extensive refining and chemical engineering. This results in a more energy-intensive manufacturing process compared to conventional oil.

However, the environmental impact story doesn't end at production. Oil change frequency plays a crucial role in overall lifetime waste generation. Synthetic oils, known for their enhanced durability and resistance to degradation, often allow for extended oil change intervals. This translates to less frequent oil changes, reducing the total volume of used oil generated over the lifespan of a vehicle. Conventional oils, while generally requiring more frequent changes, are seeing advancements in formulations. For example, Valvoline NextGen utilizes 50% recycled oil in some of its conventional formulations, contributing to a circular economy approach.

Emissions during vehicle operation also vary depending on the type of oil used. High-quality synthetic oils can improve fuel efficiency due to reduced friction, leading to lower greenhouse gas emissions. While the higher energy input during synthetic oil production is a factor, studies suggest that the overall benefit from reduced emissions during vehicle operation can outweigh the production footprint. ExxonMobil, for instance, has published emissions calculations demonstrating a net environmental benefit from using synthetic oil despite its higher production energy requirements. Furthermore, some synthetic oils like AMSOIL achieve API's lowest oil consumption rating, further minimizing emissions and environmental impact.

Tips for Eco-Conscious Motorists:

Key Players in Sustainable Lubrication:

This item deserves a place on this list because the environmental impact of our choices, even seemingly small ones like motor oil, is becoming increasingly critical. By understanding the nuances of synthetic vs. conventional oil in terms of resource consumption, emissions, and waste generation, consumers can make informed decisions that align with their environmental values and contribute to a more sustainable future. This is particularly relevant for our target audience, which includes families concerned about the environment and small business fleet managers looking to minimize their ecological footprint.

When comparing synthetic vs. conventional oil, the price tag on the bottle is just the tip of the iceberg. A true cost analysis delves deeper, considering the long-term value proposition that extends beyond the initial purchase price. This involves evaluating overall engine longevity, required maintenance, operational expenses, and the potential for avoiding costly repairs down the line. Understanding this comprehensive cost picture helps determine the real economic impact of your oil choice over the lifetime of your vehicle.

Understanding the Costs

While synthetic oils typically cost 2-4 times more per quart than conventional oils, the extended change intervals significantly impact lifetime maintenance costs. Because synthetic oil can last considerably longer between changes, you'll purchase oil and filters less frequently, and pay for fewer labor hours for oil changes over the life of your car. This can add up to substantial savings, especially for high-mileage drivers and fleet managers.

Furthermore, the superior protection offered by synthetic oil contributes to enhanced engine longevity and a reduced likelihood of major engine repairs. This translates into significant economic benefits. Better fuel economy, even if marginal, also adds up over time, contributing to a lower overall operating cost.

Examples of Long-Term Savings

Real-world data consistently demonstrates the long-term cost advantages of synthetic oil:

Actionable Tips for Calculating and Assessing Value

Why Cost Analysis Matters

For Richardson commuters, families, military personnel, first responders, healthcare workers, owners of older vehicles, and small business fleet managers, understanding the true cost of oil is critical. Whether you prioritize reliability, long-term value, or maximizing your budget, a comprehensive cost analysis clarifies the value proposition of synthetic oil. It helps determine whether the higher upfront cost ultimately translates into substantial savings and peace of mind over the life of your vehicle. This analysis empowers you to make an informed decision based on your individual needs and financial goals.

| Aspect 💡 | Synthetic Oil ⭐📊⚡ | Conventional Oil ⭐📊⚡ |

|---|---|---|

| Implementation Complexity 🔄 | Higher manufacturing complexity due to chemical engineering and purity controls | Simpler refining process from crude oil with natural impurities |

| Resource Requirements 🔄 | Requires chemical processing, advanced facilities, and higher energy input | Uses crude oil refining; less energy-intensive production |

| Expected Outcomes ⭐📊 | Superior molecular uniformity, enhanced viscosity stability, better engine wear protection, longer drain intervals, improved fuel economy, and reduced emissions | Moderate performance, variable quality depending on crude source, shorter oil life, more impurities, and lower cost |

| Ideal Use Cases 💡 | Extreme temperature climates, high-performance/turbocharged engines, long service intervals, and eco-conscious users | Budget-conscious consumers, older engines, moderate climates, frequent maintenance intervals |

| Key Advantages ⭐⚡ | Consistent viscosity at extremes, 40-60% wear reduction, extended oil change intervals, fuel savings of 1-3%, lower emissions over lifetime | Lower upfront cost, proven reliable for standard applications, easier availability, beneficial for less demanding engines |

| Cost Analysis and Value Proposition 💡 | Higher upfront cost but lower lifetime maintenance and repair expenses, better engine longevity, and potential resale value premium | Lower purchase price but higher total cost due to frequent changes and increased wear-related expenses |

Choosing between synthetic vs conventional oil is a crucial decision for maintaining your vehicle's health and performance. From understanding their differing chemical compositions and manufacturing processes to weighing the long-term costs and environmental impact, making an informed decision requires careful consideration of various factors. We've explored the key differences, including viscosity stability, engine protection, longevity, fuel efficiency, and overall value. The optimal choice depends on your specific needs – whether you prioritize high-temperature performance, extended oil change intervals, maximizing fuel economy, or minimizing environmental impact. For Richardson commuters, families, military personnel, first responders, healthcare workers, and fleet managers, understanding these nuances is essential for responsible vehicle ownership. Mastering these concepts empowers you to make informed decisions that directly impact your vehicle's lifespan, performance, and operating costs.

Whether you're driving an aging vehicle, a high-mileage workhorse, or managing a fleet of company cars, the right oil can significantly impact your bottom line and peace of mind. For personalized advice tailored to your driving conditions and vehicle, trust the experts at Kwik Kar Oil Change and Auto Care. We offer expert guidance on synthetic vs conventional oil, utilizing state-of-the-art equipment and ASE-certified technicians to ensure your vehicle receives the best care. Visit Kwik Kar Oil Change and Auto Care today for a consultation and let our team help you determine the perfect oil for your vehicle and driving needs.

CLICK LINK BELOW TO LEARN MORE ABOUT OUR SERVICES

Get upto $20 OFF on all services.