Ever wonder how your car’s wheels spin so freely while carrying thousands of pounds down the road? The magic behind that smooth motion is a small but incredibly tough component called the wheel bearing.

Think of it as the ankle joint of your car—it’s the critical connection that allows your wheel to rotate smoothly while bearing the vehicle's entire weight. Without it, your car wouldn’t be going anywhere.

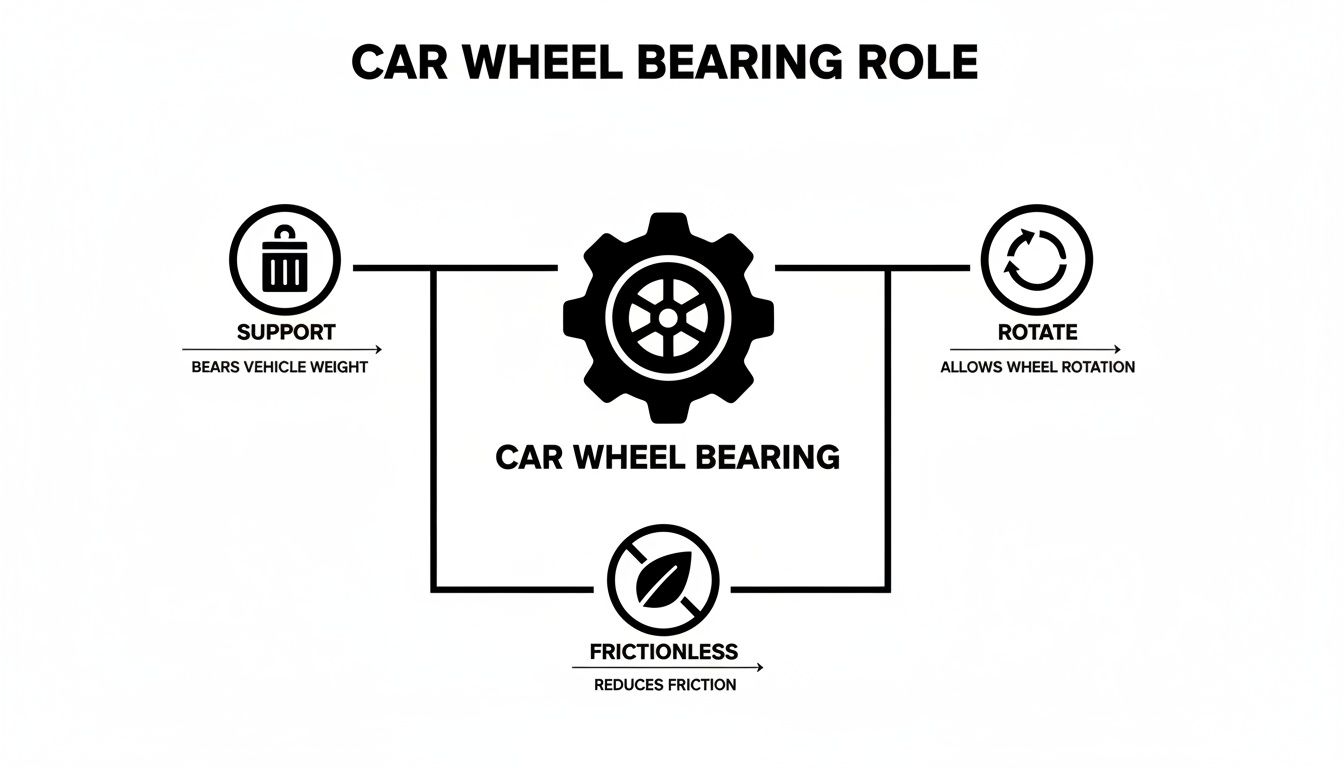

Unpacking the Role of a Wheel Bearing

At its most basic, a wheel bearing is a set of super-strong steel balls or rollers, all held together inside a metal ring called a race. This whole assembly is tucked away inside the wheel hub, which is the part that connects your wheel to the axle.

Its main job? To defeat friction. If you had direct metal-on-metal contact between the spinning wheel and the stationary axle, the heat and resistance would be immense. Your car would grind to a halt almost immediately.

Imagine trying to spin a heavy bowling ball on a concrete sidewalk. It would wobble, grind, and stop almost instantly. Now, picture that same ball spinning on a bed of smooth marbles. It would turn for a long, long time. The wheel bearing acts just like those marbles, creating a low-friction surface for the wheel to glide on. That simple idea is what makes a smooth, efficient ride possible.

Why This Little Part Is a Big Deal

The wheel bearing does more than just cut down on friction. It’s also responsible for carrying the entire weight of your vehicle, taking on massive forces every single time you hit the gas, brake, or steer around a corner.

A healthy bearing is what keeps your wheel securely attached and pointed in the right direction, which is non-negotiable for steering control and stability. The idea of using rollers to make things move easier isn't new; in fact, Philip Vaughan, a Welsh inventor, patented a design for ball bearings on carriage axles way back in 1794. You can learn more about the history of ball bearings and their evolution.

In essence, the wheel bearing is the unsung hero that makes motion possible. It's what turns engine power into smooth wheel rotation, getting you safely down the highway or through Richardson's city streets.

A Quick Summary of Its Function

To really boil it down, let’s look at exactly what a wheel bearing does, where you'll find it, and why keeping it in good shape is so critical for safe driving.

Wheel Bearing at a Glance

This table gives a quick snapshot of the wheel bearing's fundamental role and importance.

| Key Aspect | Description |

|---|---|

| Primary Purpose | To allow the wheel and tire assembly to rotate with minimal friction. |

| Location | Housed within the wheel hub, connecting the wheel to the vehicle's axle. |

| Main Job | Supports the full weight of the vehicle while the wheels are in motion. |

| Consequence of Failure | Can lead to steering issues, uneven tire wear, and in severe cases, wheel detachment. |

As you can see, this small part has a massive job. Understanding its function is the first step toward recognizing when something might be going wrong.

How a Wheel Bearing Actually Works

To really get what a wheel bearing does, you have to picture what’s happening inside this small but mighty part. Think of a set of super smooth, polished steel balls rolling along a perfectly circular track, all sealed up. That’s the basic idea. This simple design is what lets a heavy wheel spin almost without any friction, even under tons of pressure.

The whole thing is made of just a few key pieces working together. You have the inner and outer metal rings, called races, which form the "track" for the tiny rollers. The rollers themselves are the heart of the operation—they can be perfectly round ball bearings or little cylinders called roller bearings.

A little piece called a cage keeps all those rollers perfectly spaced out so they don't jam into each other. The entire unit is packed with a special high-temperature grease to keep everything moving smoothly and is usually sealed tight to block out the water, dirt, and road grime that would otherwise wreck it.

Managing Different Types of Force

A wheel bearing’s job is more than just spinning. It’s also about wrestling with some serious forces that are trying to pull your wheel in different directions. Every time you drive, your car's wheels are dealing with two main kinds of force, or load, that the bearing has to handle at the same time.

- Radial Load: This is the force of your car's weight pushing straight down. Imagine standing on a skateboard—the downward pressure on the wheels is a perfect example of radial load.

- Axial Load (or Thrust Load): This is the sideways force you feel when you take a turn or swerve to change lanes. As you steer, your car's momentum pushes against the side of the wheels, and the bearing has to be strong enough to resist that push and keep the wheel from wobbling.

A good wheel bearing is engineered to take on both of these forces simultaneously. This is what keeps your wheel firmly planted on the pavement and pointing exactly where you want it to go, whether you're navigating a tight corner on the George Bush Turnpike or just cruising straight down Central Expressway.

This simple breakdown shows the three main jobs a wheel bearing has to do to keep your car moving safely and smoothly.

As you can see, it’s a tough job: support the vehicle, let the wheel spin freely, and do it all with as little friction as possible for better control and efficiency.

The Evolution from Grease Guns to Sealed Hubs

Wheel bearing technology has come a long way. If you worked on cars a few decades ago, you’d be familiar with "serviceable" bearings. These required you to periodically take them apart, clean out all the old gunk, and repack them by hand with fresh grease. It was a messy but critical piece of car maintenance.

But the real game-changers came much earlier, helping to kickstart the whole Industrial Revolution. In 1898, Henry Timken patented the tapered roller bearing, a genius design perfect for the heavy loads of wagons and, very soon after, cars. Just a few years later, in 1907, Sven Wingquist of SKF invented the self-aligning ball bearing. These weren't just for automobiles; these inventions cut friction in all kinds of machinery by a staggering 90% compared to older, simpler designs. You can actually dig into the history of these mechanical marvels) to see how they changed everything.

Today, most modern cars and trucks use sealed wheel hub assemblies. These are sophisticated, all-in-one units that come lubricated and permanently sealed right from the factory.

This modern approach has some huge benefits:

- Durability: Being sealed makes them incredibly resistant to water, dirt, and road salt—the top three enemies of any bearing.

- Maintenance-Free: You never have to think about cleaning or repacking them with grease. It’s one less thing to worry about.

- Precision: They are built to incredibly tight specifications and often have sensors for your car's Anti-lock Braking System (ABS) and traction control built right in.

The only downside to this incredible technology? When a modern sealed bearing fails, it can’t be fixed or serviced. The entire hub assembly has to be replaced as a single part, which makes the job a bit more involved than it was on older cars.

Tuning In to the Telltale Signs of Failure

A wheel bearing rarely fails without warning. Your car is actually a pretty good communicator, and when a bearing starts to go bad, it sends out some very distinct signals through sounds and feelings. Learning to interpret these clues is the key to catching the problem early, before it turns into a much bigger—and more dangerous—issue down the road.

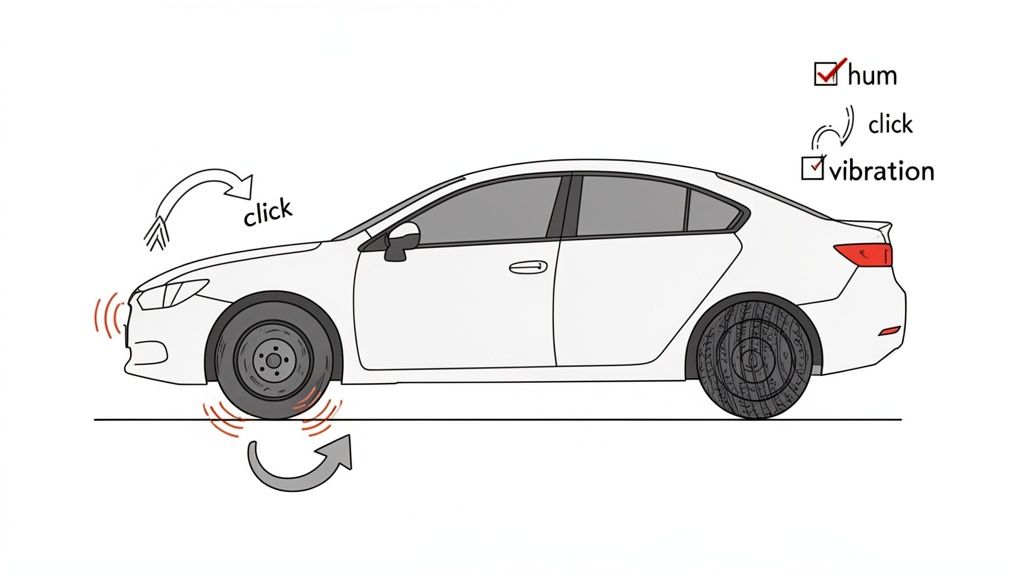

The most obvious signs of a failing wheel bearing are the noises it makes. You’ll need to listen closely to your car, especially as you speed up, slow down, or make turns. These are not normal vehicle sounds, and they should never be ignored.

Decoding the Noises

The sounds a bad bearing makes can change depending on how fast you're driving or if you're turning. At first, they might be subtle enough to blend in with regular road noise, but they will absolutely get louder and more persistent over time.

Humming or Growling: This is the classic symptom. It often starts as a faint hum that gets progressively louder as you accelerate. The sound might seem to come from one side of the car and can sound a bit like you’re driving on a rumble strip.

Clicking or Snapping: A distinct clicking or popping noise, especially when you're turning, is another major red flag. This usually means there's too much play or movement inside the bearing, which points to significant wear.

Grinding or Squealing: If the problem has been ignored for a while, the noise can escalate into a harsh grinding or a high-pitched squeal. This is a very serious warning. It means the bearing has lost its internal grease and is now creating intense metal-on-metal friction.

These sounds are your car’s way of screaming for help. The sooner you get it diagnosed, the safer you'll be.

Feeling the Problem

It's not just about what you hear. A bad wheel bearing also creates physical sensations you can feel through the steering wheel, the floor, or just in how the car handles. These symptoms tend to show up as the bearing wear gets worse.

One of the most common things you'll feel is a vibration in the steering wheel. This shaking typically gets worse as you pick up speed and may seem to come and go. If this sounds familiar, our guide on why your wheel shakes when braking might offer some more insight.

Another key symptom is your car pulling to one side. A worn bearing creates drag on that wheel, causing a slight but noticeable pull toward the bad side. You might find yourself constantly correcting the steering wheel just to drive in a straight line.

Key Takeaway: A failing wheel bearing is not just a noise issue; it's a direct threat to your vehicle's stability and control. The vibrations, steering pull, and unpredictable handling it causes are all indicators of a component that can no longer do its job of keeping your wheel secure.

Finally, take a look at your tires. A loose or wobbly wheel from a bad bearing will cause uneven and rapid tire wear. If one tire is wearing down much faster on the inside or outside edge compared to the others, a failing bearing is a likely culprit.

Symptom Diagnostic Checklist

To help you connect the dots between what you're hearing and feeling and what might be going on, here’s a quick diagnostic table. It can help you gauge the seriousness of the situation before you bring your vehicle in for a professional look.

Symptoms of a Bad Wheel Bearing

| Symptom (What You Hear or Feel) | What It Likely Means | Urgency Level |

|---|---|---|

| Faint hum that gets louder with speed | Early stage of bearing wear. The internal raceways are starting to pit and corrode. | Medium: Schedule an inspection soon. |

| Loud, constant growling or roaring | Advanced wear. The bearing is creating significant friction and is nearing failure. | High: Stop driving if possible and seek immediate service. |

| Clicking or popping when turning | Excessive play in the bearing. The internal components are loose and unstable. | High: This indicates a serious lack of stability in the wheel. |

| Steering wheel vibration | The bearing is no longer allowing the wheel to spin smoothly, creating an imbalance. | Medium to High: The vibration will worsen and affect control. |

| Car pulls to one side | The failing bearing is creating drag on one wheel, impacting alignment and steering. | Medium: This will cause premature tire wear and handling issues. |

| ABS light is on | The integrated wheel speed sensor in the bearing hub has failed or is sending bad data. | Medium: Your anti-lock braking system may not function correctly. |

Recognizing these symptoms is your first line of defense. By tuning in to your vehicle and acting on these warnings, you can address a wheel bearing issue before it escalates into a dangerous failure on the road.

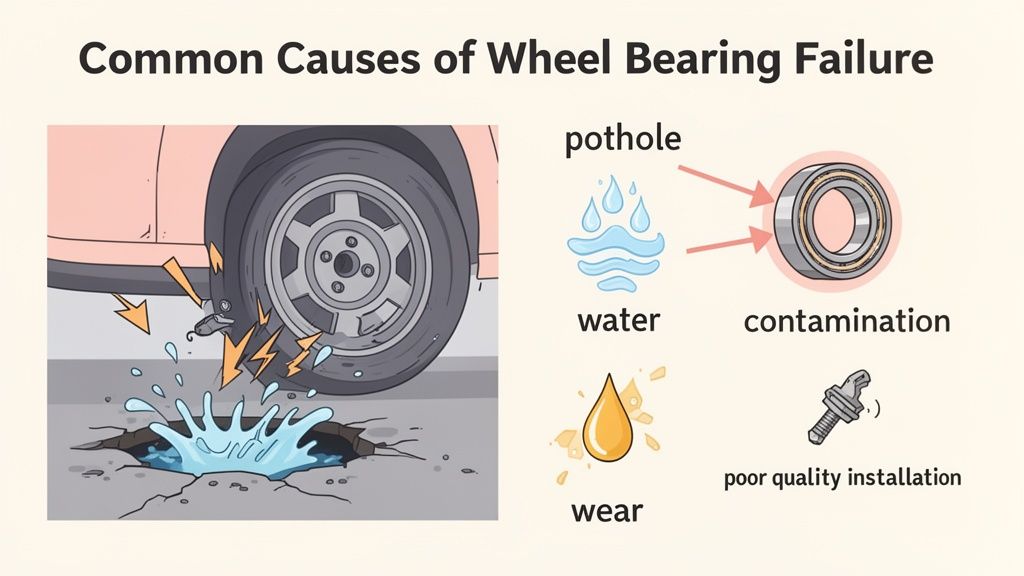

What Causes Wheel Bearings to Fail

Wheel bearings are tough little components, engineered to handle incredible forces for tens of thousands of miles. But they aren't invincible. A handful of common culprits can slash their lifespan, leading to those tell-tale noises and vibrations that spell trouble. Figuring out what those are is the first step in protecting them.

The biggest enemies of a wheel bearing? Sudden, harsh impacts. Think about driving around Richardson and hitting an unexpected pothole or clipping a curb. That jarring force sends a shockwave right through the tire and into the bearing, which can easily dent the smooth metal raceways or even crack the tiny rolling elements inside.

Even a minor imperfection from an impact can throw off the bearing's perfect, smooth operation. Over time, that tiny flaw becomes the starting point for premature wear and, eventually, complete failure.

Contamination and Moisture

Modern wheel bearings are sealed units, specifically designed to keep their lubricating grease in and all the nasty stuff out. But if that seal gets compromised, even slightly, the trouble starts brewing. Water is especially destructive.

Driving through a high-water patch or even just the constant spray from wet roads can allow moisture to sneak past a damaged seal. Once inside, water contaminates the grease, washing it away from the metal surfaces it's supposed to protect. This leads to rust on the bearings and races, creating a rough, abrasive surface that quickly chews up the component from the inside out.

Fine particles of dirt, sand, and road grit can also work their way inside. These act like sandpaper, grinding away at the polished surfaces every single time the wheel turns and accelerating wear dramatically.

Wear, Tear, and Thermal Stress

Even if you drive on perfect roads, nothing lasts forever. The constant load and rotation eventually cause metal fatigue. A wheel bearing on a typical car rotates hundreds of millions of times over its service life, and that simple, repetitive stress slowly wears everything down.

Heat is another huge factor, especially during our brutal Texas summers. The global bearing market is a massive industry, topping $120 billion a year, with automotive wheel bearings making up about 30% of that. Here in the U.S. alone, bearing issues lead to 1.5 million replacements annually. Heat is a known killer; bearings can fail 40% faster when their operating temperatures climb above 250°F—a common scenario on hot asphalt. For Richardson drivers, the extra stress from pothole-riddled roads only speeds up this wear, contributing to the 15% higher rate of suspension issues reported in Texas compared to national averages. You can learn more about the evolution of roller bearings and their manufacturing.

The combination of mileage, heat cycles, and constant load means that every bearing has a finite lifespan. For high-mileage vehicles, failure is often just a matter of time and use.

Installation Errors and Poor Quality Parts

How a wheel bearing is installed is just as important as the quality of the part itself. Replacing a modern wheel bearing often requires specialized hydraulic presses and other tools to seat it perfectly within the hub assembly.

Using the wrong tools—like a hammer or an impact wrench—can cause microscopic fractures or tiny dents that doom the new bearing right from the start. Similarly, failing to properly torque the axle nut can create too much or too little pressure, causing the bearing to wear out in a fraction of its expected lifespan.

To get long-lasting performance, it's crucial to rely on professional installation and high-quality parts. Those low-cost, unverified aftermarket bearings might not be manufactured to the same precise standards as original equipment, making them far more likely to fail prematurely. Keeping up with other maintenance, like tire rotations, can also help your bearings last longer. Check out our guide on how often you should rotate your tires for more tips.

Ultimately, ignoring the causes and symptoms of a bad wheel bearing is a serious safety gamble. A failing bearing can lead to a loss of steering control or, in a catastrophic scenario, the wheel assembly could detach from your vehicle entirely.

Navigating Wheel Bearing Replacement and Costs

Hearing you need a wheel bearing replaced can be a little intimidating, especially when you’re not sure what to expect. But getting a handle on the process and the costs involved makes the whole situation much clearer. The final price isn't some random number—it’s tied directly to your car’s specific needs.

Just know that this is a pretty common part of owning a car. On average, you can expect a single wheel bearing replacement to fall somewhere between $300 and $800. That’s a big range, and it all comes down to the details of your vehicle.

Breaking Down the Cost Factors

The price for a wheel bearing job isn't pulled out of a hat. A few key variables determine why a friend’s repair on their car might cost way more (or less) than yours.

- Vehicle Make and Model: It's no secret that parts for luxury or European cars like a BMW or Audi usually cost more than those for domestic or Japanese models. The way they're built can also mean the job takes a lot more time and effort.

- Drivetrain Type: If you have a front-wheel drive car, the suspension setup up front is often more packed in, making it tougher to get to the bearing. Throw an all-wheel drive (AWD) system into the mix, and you add another layer of complexity.

- Part Type: The biggest difference in price comes down to the type of bearing your car uses: a press-in bearing or a full bolt-on hub assembly. The bearing itself is cheaper, but it requires a special hydraulic press to get it in and out, which adds a lot of labor time. A hub assembly costs more for the part, but it's usually much quicker to swap out.

While we're talking about a specific repair, it's also smart to think about the bigger picture of vehicle upkeep. For businesses with a whole fleet of vehicles, finding efficient ways of managing overall fleet maintenance expenses can make a huge difference in simplifying operations.

The Professional Repair Process

When you take your car to an experienced technician, they follow a careful, methodical process. This isn't just about swapping a part; it's about making sure the new bearing will last for tens of thousands of miles.

First, a thorough diagnosis confirms which bearing has failed. Then, the technician lifts the vehicle, removes the wheel, and starts taking apart the brake components—caliper, rotor, the works—to even get to the hub.

Next is the tough part: getting the old bearing out. If it’s a bolt-on hub, it’s a relatively simple unbolting job. But if you have a press-in bearing, the entire steering knuckle often needs to be removed from the car. From there, a powerful hydraulic press is used to push the old bearing out and press the new one in with perfect alignment.

Critical Insight: For press-in bearings, using a hydraulic press is the only way to do it right. Trying to bang it in with a hammer is a surefire way to damage the new bearing, guaranteeing you'll be back for another repair in no time.

Once the new bearing or hub is installed, everything is meticulously put back together. The technician will torque the axle nut to the exact factory spec, which is a make-or-break step for setting the right pressure on the bearing. Finally, they’ll take it for a test drive to make sure that annoying noise is gone for good.

DIY vs. Professional Service

It's tempting to think about doing this job yourself to save a few bucks, but wheel bearing replacement is one of those repairs where experience and special tools really matter. Without a hydraulic press for those press-in bearings, you’re pretty much out of luck.

Even with the "easier" bolt-on hubs, a small mistake like over-tightening the axle nut can destroy the brand-new part in just a few hundred miles. The risks of a DIY attempt gone wrong are high—you could end up with an even more expensive repair bill and a serious safety hazard. Trusting the job to a certified professional ensures it’s done right the first time, giving you confidence and true peace of mind on the road.

When you’re dealing with something as critical as a wheel bearing, you can't afford to take chances. You need a team you can trust, and for drivers all over Richardson, that team is right here at Kwik Kar. We’ve earned our reputation one repair at a time by focusing on real expertise, honest communication, and a genuine commitment to keeping our neighbors safe on the road.

It really comes down to our technicians. Our team is made up of ASE-certified professionals who live and breathe this stuff. They have the hands-on experience to pinpoint a wheel bearing problem quickly and accurately, and they know the specific quirks of different makes and models. We don't just throw parts at a problem; we diagnose with precision and fix it right the first time.

Our Commitment to Quality and Transparency

A repair is only as good as the parts you use. That's why we exclusively install high-quality, NAPA AutoCare-backed parts. This isn't just a logo to us—it's a promise that every wheel bearing we install is built for the long haul, giving you confidence mile after mile. For service centers like ours, staying on top of our game means investing in the best tools and processes, often including specialized Lista Automotive solutions.

We also believe you should feel completely confident in your choice of auto shop. As a CARFAX and RepairPal certified shop, we operate with total transparency. These certifications aren't easy to get; they're a reflection of our commitment to fair pricing, honest work, and customer satisfaction that’s been verified by real drivers just like you.

Your safety is our top priority. A properly installed wheel bearing is essential for vehicle control, and our meticulous process ensures every component, from the bearing to the alignment, works together perfectly.

Because a new wheel bearing can affect your vehicle's geometry, a precise wheel alignment check is an integral part of our replacement service. This final step guarantees your car drives straight and helps your tires wear evenly after the job is done.

Finally, we’re proud to be part of the Richardson community. We show our appreciation by offering service discounts to military personnel, first responders, and healthcare workers—it’s just a small way to say thank you to those who do so much for all of us. At Kwik Kar, you’re not just another repair order; you're our neighbor.

Got Questions About Wheel Bearings? We've Got Answers.

Alright, let's wrap this up by hitting some of the most common questions we hear from drivers around Richardson. This is where the rubber meets the road, so to speak—just straightforward answers to help you understand what's going on with your car and what to do next.

How Long Do Wheel Bearings Last on Texas Roads?

That's the million-dollar question, isn't it? In a perfect world, most modern wheel bearings are built to go the distance, typically lasting anywhere from 85,000 to 100,000 miles. But we don't live in a perfect world; we live in Texas, and our roads can be tough on a car.

Here in the Richardson area, a few things can really shorten that lifespan:

- Pothole Problems: Hitting a nasty pothole, smacking a curb, or even just running over road debris can jolt the bearing and cause instant damage to its delicate internal parts.

- Texas Heat: Those scorching summer days aren't just uncomfortable for you. They dramatically raise the temperature of every part of your car, including the wheel bearings. This intense heat can break down the grease inside, leading to friction and premature failure.

- Surprise Showers: Driving through high water after a heavy rainstorm can be a bearing's worst enemy. If moisture gets past the seals, it leads to rust and contamination that will chew up the bearing from the inside out.

With these factors in play, it’s not at all uncommon for a bearing to give out earlier than expected. This is exactly why regular vehicle inspections are so important—they help us catch the problem before it leaves you stranded.

Is It Safe to Drive with a Bad Wheel Bearing?

Let me be blunt: no, it is not safe. You might be tempted to ignore that faint humming noise for a little while, but driving on a bad wheel bearing is a gamble you don't want to take. The problem never gets better on its own; it only gets worse and more dangerous.

A failing bearing creates looseness, or "play," in your wheel, which directly impacts your control over the vehicle. You might feel it as a vibration in the steering wheel or notice your car handling strangely. In a worst-case scenario, the bearing could completely seize, causing the wheel to lock up while you're moving. Even worse, it could fail so catastrophically that the wheel assembly detaches from your vehicle.

Safety First: The second you suspect a wheel bearing problem—whether it's a hum, a grind, or a wobble—your next stop should be a trusted auto shop. Don't put it off. Ignoring the warning signs just isn't worth the risk to you or anyone else on the road.

How Does a Failing Bearing Affect My ABS System?

This is a great question, and it highlights how interconnected modern cars are. On most vehicles today, the Anti-lock Braking System (ABS) sensor is built right into the wheel bearing hub. This sensor is what tells your car's computer how fast each wheel is spinning, allowing the ABS to work properly in a panic stop.

When a wheel bearing starts to fail, the resulting wobble and vibration can easily damage that sensitive ABS sensor or disrupt its signal. This is why a bad bearing will often trigger the ABS warning light on your dashboard. When that light is on, it means your anti-lock braking system is likely offline, which seriously compromises your ability to stop safely in an emergency. So, a bad bearing isn't just a mechanical issue—it's a safety system failure waiting to happen.

For a professional diagnosis and expert wheel bearing service you can trust, bring your vehicle to Kwik Kar Oil Change and Auto Care. Our ASE-certified technicians in Richardson are ready to ensure your ride is safe and smooth. Schedule your appointment today at https://www.kkrichardson.com.